IC Layout Basics

Table of Contents

- CMOS process

- CMOS Inverter cross-section

- Mask-related effects, distortion of light

- CMOS transistors. Fingers and Multipliers

- Capacitors

- Resistors

1.CMOS process

Fabrication of the CMOS integrated circuit is a multistep process, that takes a lot of efforts to achieve good performance and yield. Manufacturing of the IC is very similar to cooking a very tall and fancy burger - it starts from the substrate (bottom bun), adding different layers to create structures (cheese, lettuce, patty) and covering everything with a top metal and protection oxide (top bun). You can see the simplified manufacturing process and the typical IC cross-section on the image below.

IC Cross-section and manufacturing steps

2. CMOS Inverter cross-section

Let's have a look on a very basic circuit - CMOS inverter in layout. CMOS inverter contains just 2 devices - PMOS and NMOS transistors. Both devices are manufactured in the substrate of a p-type. In a standard CMOS process, PMOS device is manufactured in NWELL (n-type pocket) and NMOS is manufactured in p-substrate (or PWELL). P-substrate is connected to ground and NWELL is connected to the supply voltage (VDD). This measure is used to ensure correct device performance and prevent latch-up.

CMOS inverter cross-section

Because PMOS device is formed in its own well, the body of the PMOS (NWELL) can be connected to any potential, required by design, not necessarily to VDD. On the other hand, the body of the NMOS device has to be connected to the ground only, because it is formed in a substrate, which should always be connected to the ground.

Standard process summary:

- PMOS body can be connected to any potential;

- NMOS body can be connected only to ground (shorted to the substrate);

Substrate connection in standard CMOS process

In a Deep-NWELL (or triple-well) process, the PWELL of the NMOS device is separated from the p-substrate by the Deep NWELL, which allows designers to connect the body of the NMOS device to any potential, like in PMOS. This allows better design flexibility, but at the cost of the area, occupied by extra wells. Moreover, Deep-NWELL is very effective in insulating sensitive devices from the substrate noise.

Substrate connection in Deep NWELL CMOS process

Deep NWELL connections:

- P-sub is connected to ground;

- NWELL is connected to the supply potential (VDD);

- Internal PWELL is connected to any potential required by design.

Deep NWELL process summary:

- PMOS body can be connected to any potential;

- NMOS body can be connected to any potential;

- Can be used to insulate sensitive devices from the substrate noise;

- Requires more layout area;

- More expensive to manufacture (requires extra mask).

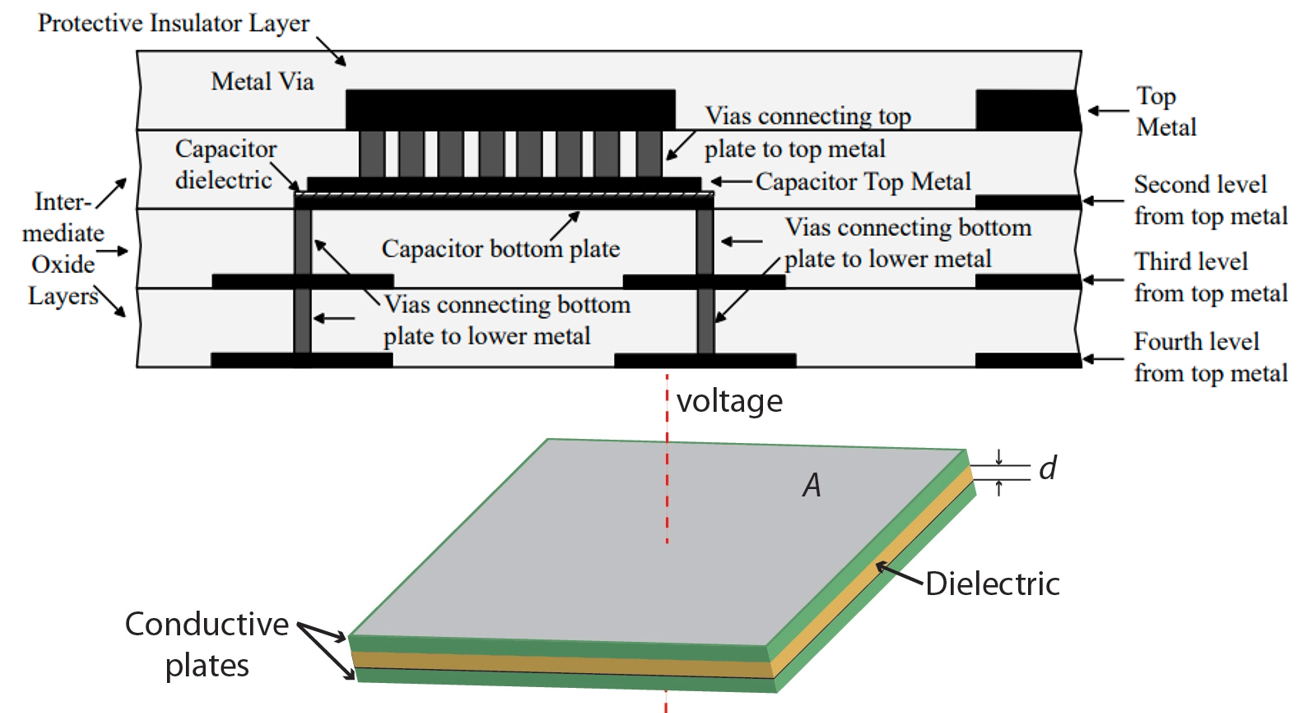

3. Mask-related effects, distortion of light

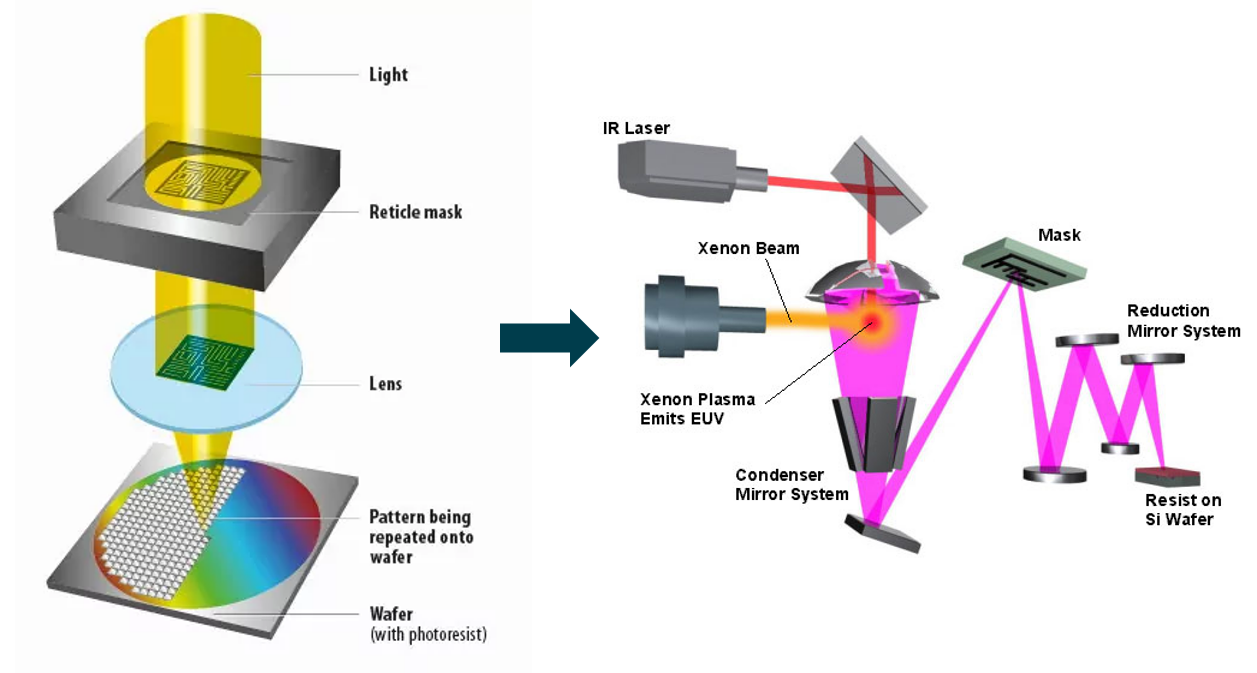

Lithography is a key process in the fabrication of CMOS devices. It involves using light (usually extreme ultraviolet, EUV) to transfer patterns from a mask onto a thin layer of photosensitive material, called photoresist, that covers the silicon wafer. The process starts by coating the substrate with a photosensitive material known as a photoresist. A photomask, which contains the desired pattern, is then positioned over the photoresist. Light is projected through the photomask, selectively exposing specific regions of the photoresist. This exposure causes a chemical change in the affected areas, making them either soluble or insoluble in a developer solution. Once developed, the pattern is transferred onto the substrate using techniques such as etching, chemical vapor deposition, or ion implantation.

Photolithography process

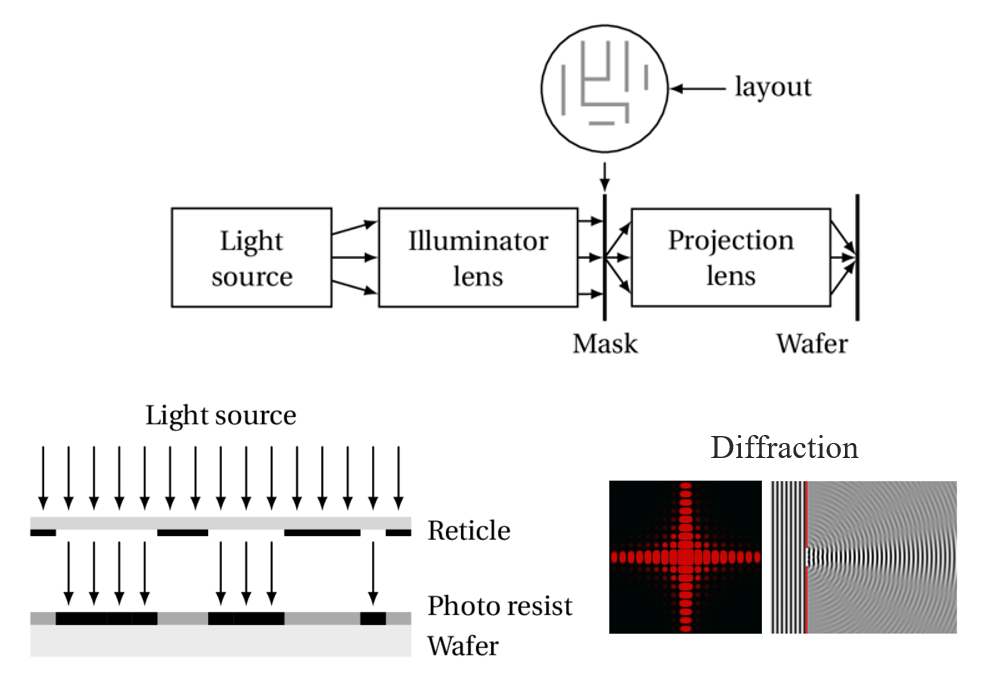

In the early days of semiconductor manufacturing, lithography involved feature sizes much larger than the wavelength of light used. Today, feature sizes have shrunk to dimensions smaller than the wavelength of even ultraviolet light. This mismatch causes significant deviations between the intended mask design and the actual features printed on the wafer.

Photolithography process

Optical Proximity Correction (OPC) is an advanced mask engineering technique designed to improve the accuracy of transferring a layout pattern onto a wafer. It achieves this by modifying the mask geometry to compensate for predictable distortions that occur during imaging and subsequent processing steps.

Pattern distortion and correction through OPC

4. CMOS transistors. Fingers and Multipliers

In the analog design, we often use large-sized transistors, that help us achieve desired gain or current. Usually, such transistors have a large ratio which makes them more sensitive to the manufacturing and temperature gradients. Moreover, matching is often required for such devices. For these purposes, transistors are folded by using fingers or multipliers. The main difference between fingers and multiplier is that multipliers are separate devices, where fingers are stacked to form a single device.

Single-finger device parasitics

Fingers are serving one more important purpose in analog design - parasitics reduction. When we have a single device with the width and length , the main device parasitics are the source-bulk capacitance and the drain-bulk capacitance . If the same device has 2 fingers, width each and length , then the source (or drain) area will be shared between them. This will lead to the parasitics being , and . Therefore, the parasitic capacitance of the drain area is reduced by half, which positively affects the speed of the device. Also, because the drain area is shared, drain resistance is also reduced by half.

Multi-finger device parasitics

Apart from this, the polysilicon gate of the MOSFET has also some substantial resistance, making the gate voltage potential distribution uneven hereby negatively affecting the performance. In the case of the two-finger device, the gate will look like two hal-sized resistors in parallel, reducing the total resistance by the factor of 2.

Key points of using fingers:

- Reduced parasitic capacitance of the drain/source;

- Reduced parasitic resistance of the drain/source;

- Reduced gate resistance;

- Improved speed and resistance of the device;

- Reduced area;

- Simplified matching;

5. Capacitors

5.1 Capacitor Types in CMOS Technology

In CMOS technology, there are three main types of capacitors:

- MOS Capacitor

- Metal-Oxide-Metal (MOM) Capacitor

- Metal-Insulator-Metal (MIM) Capacitor

Capacitor types

5.2 Metal-Oxide-Semiconductor (MOS) Capacitors

A Metal-Oxide-Semiconductor (MOS) capacitor functions similarly to a transistor used as a capacitor.

In this structure:

- The gate serves as the top plate of the capacitor.

- The drain and source connections form the bottom plate.

- The thin oxide layer under the gate acts as the insulator layer.

MOS capacitor

The capacitance of a MOS capacitor varies with the DC voltage applied to the gate. Changes in gate voltage affect the depletion region, altering the dielectric properties and thus modifying the capacitance. MOS capacitors are particularly well-suited for local supply decoupling applications, where the DC voltage remains constant.

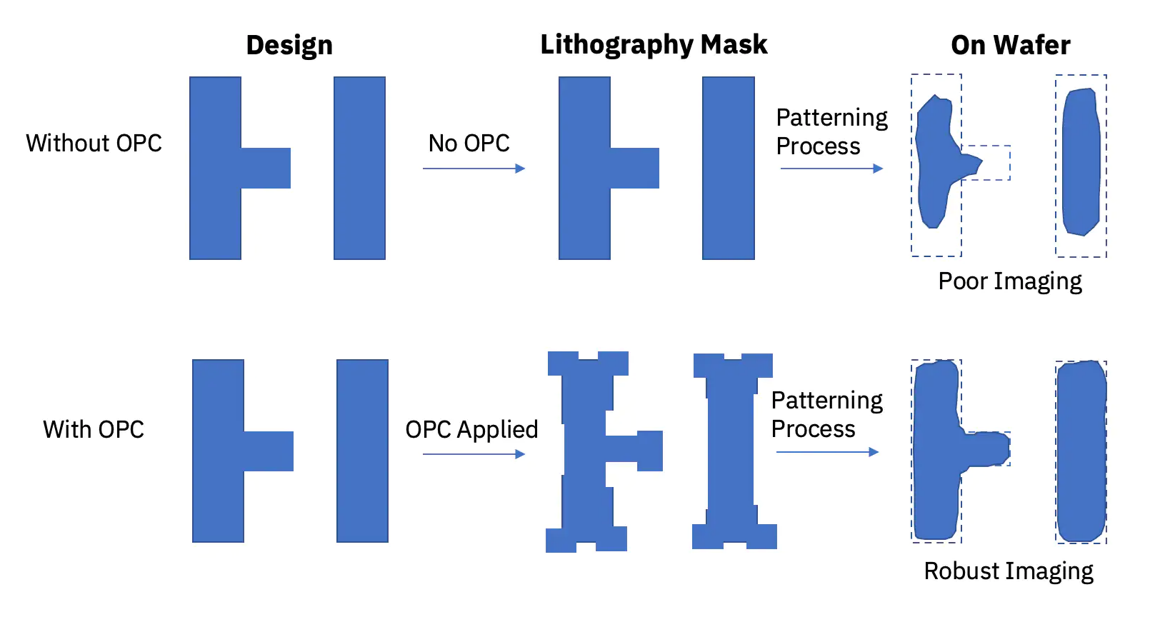

5.3 Metal-Insulator-Metal (MIM) Capacitors

Metal-Insulator-Metal (MIM) capacitors are a type of capacitor which function similarly to a parallel-plate capacitor, where metal plates (electrodes) are separated by an insulating dielectric material.

MIM capacitor

To maximize capacitance, MIM capacitors are often built using a three-plate structure. This structure enhances capacitance density while maintaining stable performance and low leakage current, due to the high-quality dielectric material used in their construction. Moreover, MIM capacitors have a high quality factor which makes them very suitable for RF applications. Main drawbacks of this type of capacitor is that MOM capacitor manufacturing requires extra mask (and corresponding layer of dielectric) and different parasitics for top and bottom plates, which should be taken into account while designing the circuit.

5.4 Metal-Oxide-Metal (MOM) Capacitors

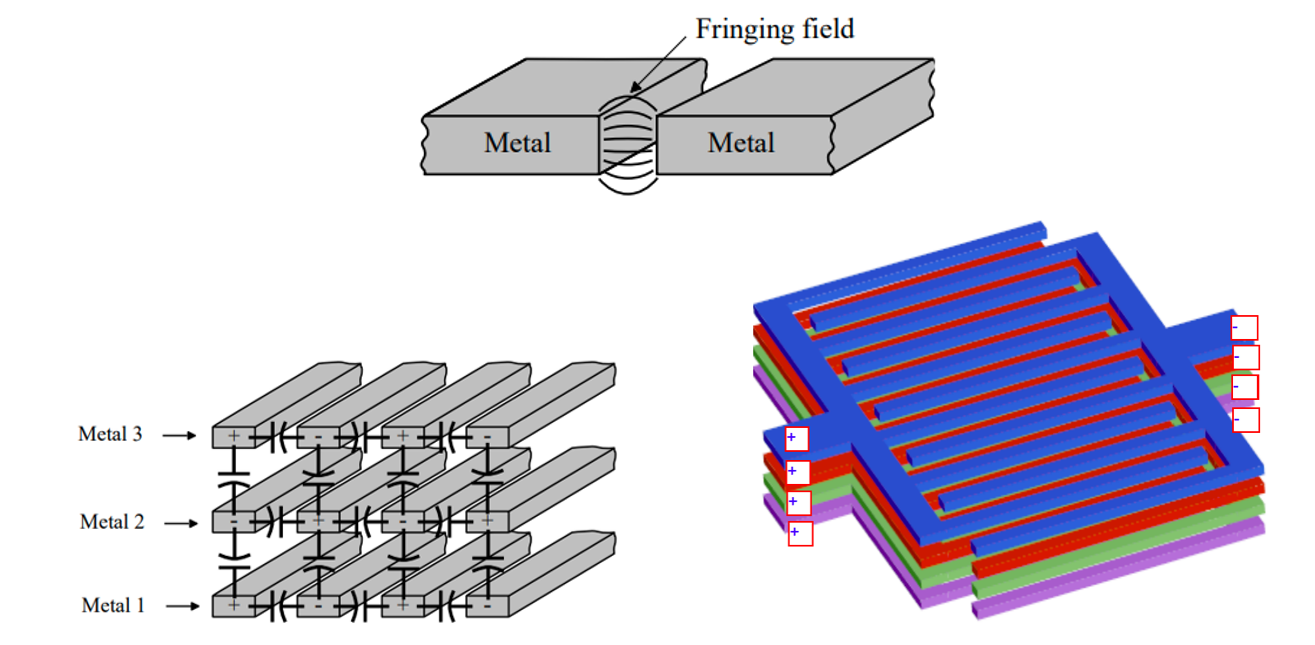

Metal-Oxide-Metal (MOM) capacitors - is an interdigitated, multi-finger structure formed by metal layers, with the fingers interlocking like the clasped fingers of two hands. The plates of the capacitor are created using standard metal wiring lines, and optionally stitched through vias. The required capacitance is produced by the combination of plate-to-plate and fringe capacitances.

MOM capacitor

In earlier technology nodes (350nm to 90nm), the MOM capacitor was the preferred choice. However, as technology scaled below 65nm, fringe capacitance became dominant. The MIM capacitor utilizes both fringe capacitance and plate-to-plate capacitance, forming an efficient 3D structure ideal for advanced nodes.

Dominating type of capacitance vs. process node

The fringe capacitance provides good matching characteristics compared to vertical coupling, primarily due to the enhanced process control of lateral dimensions rather than the thickness of metal and dielectric layers. To further increase capacitance density, multiple metal layers can be connected in parallel through vias, forming a vertical metal wall or mesh. The lowest metal layers (such as M1–M5) are typically used in MOM capacitors to maximize capacitance density, as these layers have the smallest metal line width and spacing. This type of capacitors does not require an extra mask which makes them a very low-cost devices. Main drawbacks of this type of capacitor is that it has higher series inductance and resistance, as well as occuping routing metal layers, which makes routing more complicated.

5.5 Capacitor types comparison

Here is the summary of the capacitor types in IC design:

Capacitor types comparison

| MOM | MIM | MOS | |

|---|---|---|---|

| Structure | Same-layer interdigitated structure with oxide dielectric layer | Two or more metal plates separated by an insulating material | Metal gate electrode, oxide insulator layer, and semiconductor substrate |

| Capacitance density | High | Moderate to high | Moderate to high |

| Capacitance variation with voltage | Low | Low | High |

| Sensitivity to temperature | Low | Moderate | Low |

| Fabrication | Standard | Extra mask | Standard |

| Parasitics | High | Low | High |

6. Resistors

6.1 Resistor types

In CMOS technology, there are three main types of resistors:

- Diffusion resistor ( or )

- NWELL resistor

- Polysilicon resistor

Different resistor types cross-section

6.2 Diffusion resistor

Diffusion resistor - is a type of resistor which is formed in a diffusion area (as drain/source areas), separated by the WELL. Typically, the diff. resistor has a bit lower resistivity than . On the other hand, diffusion resistor has lower temperature coefficient (both TC are positive).

6.3 NWELL resistor

NWELL resistor - is a type of resistor which is formed in a well area (NWELL or PWELL). It uses the resistance of lightly doped area of the wel to form a resistor. Both diffusion and NWELL resistors are formed directly in the substrate, that's why they have a natural parasitic capacitance caused by the reverse-biased junction formed between the diffusion resistor and the opposing doping of the substrate.

6.4 Polysilicon resistor

Polysilicon resistor - is a type of resistor which is made on top of the STI layer, using polysilicon (which is primarily a gate material). The polysilicon itself is quite a resistive material, that's why when it is used to form a gate it is usually salicided (doped) to increase its conductance. More advanced versions of the polysilicon resistor can be unsalicided, in order to increase the resistivity.

Accuracy of polysilicon resistors is way higher than diffusion resistors, +-3% absolute vs. +- 35% for diffusion resistors. The temperature coefficient of polysilicon resistors is about to that of diffusion resistors, and the voltage coefficient is about half diffusion resistors. Additionally, because Polysilicon resistors are above the oxide layer, they can be laser-trimmed for higher accuracy or used as fuses without damaging the substrate.

6.5 Metal resistor

Metal resistor - is a type of resistor that uses resistivity of the routing metal. This type of resistors has a lot of drawbacks, such as low resistivity, large capacitive and inductive parasitics and sensitivity to EM requirements. But this type of resistors become very handy while creating relatively small resistors as well as net connections in schematic. The common example is the separation of the positive and negative terminals in inductor (otherwise tools will consider inductor as a plain short), creating ASIC options and programming features.

6.6 Resistor types comparison

Here is the summary of the resistor types used in IC design:

Resistor types